Improve the quality of products

The JCU Group always approaches things from the customer’s perspective, ensures reliable quality and safety, and provides detailed support to deliver safety and security to our customers.

Quality Control

The JCU Group believes that maintaining and improving quality leads to customer satisfaction and trust, and this in turn leads to sustainable growth for the entire JCU Group. This idea is the basis on which we established the JCU Quality Policy which we have defined to be our guidelines for quality management.

In addition, our Niigata Plant, Sales Office, and R&D Center in Japan are certified for international standard ISO 9001 and continue to work to control, maintain, and improve product quality. Outside of Japan, the offices listed in the table are ISO9001 certified and are committed to quality management.

JCU quality policy

We have established the following Quality Policy based on JCU’s management philosophy, social conditions, and market developments.

- Support manufacturing around the world and contribute to enriching people’s lives by pursuing new surface treatment technologies.

- Respond accurately and quickly to market demands, and pursue customer satisfaction and a larger global market share.

- Provide products and services of the same quality to all customers regardless of region or country.

In order to embody this Policy, we apply quality management systems based on ISO 9001:2015 and implement the following:

- (1)Promote continuous improvement so that quality management systems are able to fully realize their effectiveness.

- (2)All departments are to formulate quality targets based on issues associated with their business and strive to achieve these targets.

- (3)Make sure that all employees are well- informed on the Quality Policy and quality management systems.

- (4)Respond to changes in conditions inside and outside the Company, and revise the Quality Policy as necessary.

Status of ISO9001 certification at overseas offices

Status of other ISO certification at overseas offices

Quality Targets

The JCU Group is implementing a variety of initiatives to strengthen its quality control system. The Niigata Plant is revising its work procedures and processes, strengthening their in-house training and safety walkthroughs, and implementing initiatives to raise awareness on human error prevention. In addition, we strive to improve productivity as well as quality consistency by maintaining the stable operation of our production lines through inspections and maintenance of aging manufacturing and utility facilities, and upgrades to manufacturing work conditions and facilities.

Disclosure of Product Related Information

JCU Group product labels display information in the format defined in the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). Product labels display information in Japanese, English and, where needed, in the language of the country to which the product is delivered as provided in the country’s laws and regulations.

Technical documentation describing the performance of and control methods for each product is prepared by the R&D Center. The contents of technical documentation are carefully examined by Sales and other departments before they are provided to customers.

We also prepare Safety Data Sheets (SDS) that conform with GHS and Japanese laws in Japanese and English. Subsidiaries outside of Japan are responsible for conformance with laws and regulations in their respective countries.

Safety Data Sheet (SDS)

This is a document that is provided by the supplier of a chemical substance or compound containing a chemical substance to its recipient at the time the substance is transferred or provided to the recipient. The document provides information regarding the substance’s physicochemical properties, hazards, toxicity, and handling. SDSs also provide information on first aid measures in the event of exposure, storage methods, and disposal methods.

*Released SDS that is compliant with the revised Chemical Substances Control Act (Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof) on April 1, 2023.

Quality Management System

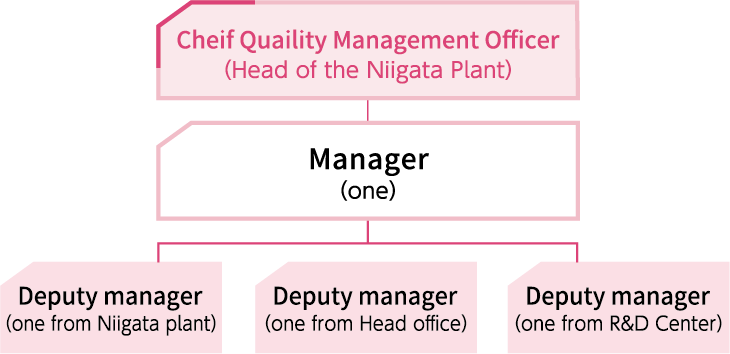

The JCU Group has set up a quality management system to realize its Quality Policy. The Head of the Niigata Plant is the Chief Quality Management Officer, under whom is assigned a manager who, along with his or her deputy manager, takes care of the Group’s quality improvement activities.

Quality management system schematic

Information Protection

In order to properly handle and protect customer and business partner information, the JCU Group prohibits the use of information obtained in the course of business for other than legitimate purposes, and strictly manages the information in accordance with our confidential information management regulations and other rules so that it is not disclosed or leaked.

In addition, JCU has established and implements a Personal Information Protection Policy.

Quality Control at the Niigata Plant

At JCU, we strive to improve quality so that we are able to provide our customers with products with solid quality, and can be used safely and with peace of mind. For this report, we spoke with Mr. Yamazaki from the Quality Assurance Department, which is responsible for product quality control, about their efforts to maintain and improve quality.

General Manager, Quality AssuranceNobuhiro Yamazaki

Professional history

After serving as manager of the CS and development department in the electronics division at the R&D Center and then, since 2018, as local manager of the Vietnam subsidiary, which also has a manufacturing plant, I became manager of the Quality Assurance Department at the Niigata Plant in April 2023.

Based on our motto of always providing products with consistent quality levels that customers can use with peace of mind, the Niigata Plant has established a rigorous management system based on a quality management system that enables mutual monitoring between manufacturing/technology and quality assurance divisions.

What we are concerned with is not only maintaining stable quality, but also building a system that does not "produce irregular products," that is, "cause irregularities in the production process." To that end, we continue to carry out improvement activities, 5S activities, process and safety walkthroughs, and utilize the PDCA cycle to further improve our quality levels.

We will also continue to provide local guidance programs and on-site audits for staff members at overseas subsidiaries so that we are able to provide the same quality and service regardless of region or country.